Product Description

1321-13-01 Double Head, 37” Wide, Widebelt Sander.

KEY FEATURES

The Timesavers Model 1321-13-01 Double Head, 37” Wide, Widebelt Sander is equipped with two top heads; an 8” diameter contact drum followed by a dual action sanding head with platen. It includes industry leading standard features designed to meet your application needs. Superior design and construction of the TimesaversModel1321-13-01 Double Head, 37” Wide, Widebelt Sander gives you the competitive edge.

SPECIFICATIONS

Abrasive belt size: 37”x60”

Main Motor: 15 HP & 10 HP

Maximum width stock: 36"

Minimum part length: 13"

Maximum thickness opening: 5"

Feed speed: 15-45 FPM

Voltage/Phase/Frequency: 230/3/60

Full load amps @ 230 volt: 80*

Motor type: TEFC

Passline height: 33”-38”

Dust extraction: 2000 CFM (5” static pressure)

Compressed air usage: 4 CFM @ 90 psi

Approximate shipping weight: 4,200 lbs.

STANDARD FEATURES

8” Diameter Contact Drum (first head position): A dynamically balanced 8” diameter contact roll with precision bearings.

Dual Action Sanding Head: (second head position): Combination head with a 4 ¾” diameter contact drum and 2 ½” wide platen allows for both calibrating and finish sanding with same head.

15 & 10 Horsepower Main Drive Motors: Abrasive head drive motors and other motors are precision balanced for power and long life. Totally enclosed, fan-cooled motors add durability.

Four Jack Bed Construction: Four heavy duty precision jacks, one supporting each corner of the conveyor bed assembly.

Dual Infeed and Dual Outfeed Holddown Rolls: Rubber-covered, spring-loaded rolls aid in holding parts onto the conveyor belt as they pass through the machine.

Air Operated Disc Brakes: Used to stop the abrasive head to assure consistent abrasive belt stoppage in approximately four seconds. This braking system will not fade under continuous braking and has non-sparking, easily replaceable linings. The brake disc is located on the main motor shaft for easy maintenance.

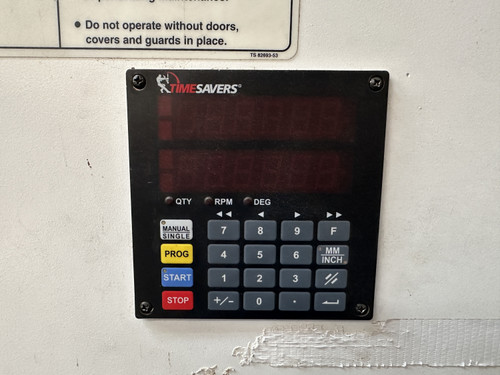

Centralized Control Panel: Simple operator controls for machine operation. Conveyor feed and abrasive belt heads are controlled at this centralized location.

Infeed Stop Bar: A sheet metal gate acts as an emergency stop for the operator when loading the machine. The gate actuates a limit switch, which shuts down the abrasive belt heads and conveyor in emergency situations.

Hour Meter: Records actual running time of the machine. This unit is used by maintenance for scheduled lubrication of key components.

Main Motor Percentage Load Meter: Provided on each sanding head to show the exact percentage of main motor horsepower being used during operation.

Motorized Thickness Adjustment: Conveyor bed setting is motor driven. Allows for changes in thickness settings of material to be processed.

Through-Beam Abrasive Belt Tracking: Electronic photo-eye tracking which monitors and controls abrasive belt movement on the grinding head. Over-travel limit switches prevent abrasive belt damage in case of mistrack.

Quick Release Outboard Support: Allows fast removal of outboard support to expedite abrasive belt change.

Abrasive belts can be changed in approximately one minute.

Variable Speed Conveyor Drive: 15-45 FPM A/C variable frequency conveyor drive allows operator to change feed speed by simply turning a dial, even while running parts.