Product Description

2321-24-21 Double Head, 43” Wide, Planer Sander.

KEY FEATURES

The Timesavers Model 2321-24-21 Double Head, 43” Wide, Planer Sander is equipped with two top heads: a 6” diameter carbide insert cutter head followed by a dual action sanding head with platen. It includes industry leading standard features designed to meet your application needs. Superior design and construction of the TimesaversModel2321-24-21 Double Head, 43” Wide, Planer Sander gives you the competitive edge.

SPECIFICATIONS

Abrasive belt size: 43”x75”

Main Motors: 30, 20 HP

Maximum width stock: 42"

Minimum part length: 15"

Maximum thickness opening: 5"

Minimum finished thickness with planer head: ½”

Infeed loading area: 14”

Feed Speed: 15-45 FPM

Voltage/Phase/Frequency: 230/3/60

Full load amps at 230 volt: 145*

Motor type: TEFC

Passline height: 33”-38”

Dust extraction: 4,000

Compressed air usage: CFM (5” static pressure) 2 CFM @ 90 psi

Approximate shipping weight: 6,500 lbs.

STANDARD FEATURES

7” Diameter Knife Head (1st Head): A dynamically balanced 6” diameter helical cutter head with 14 mm. carbide inserts.

Dual Action Sanding Head (2nd Head Position): Combination head with 5 ½” diameter contact drum and 2 ½” wide platen allows for both calibrating and finish sanding with same head.

30 & 20 Horsepower Main Drive Motors: Abrasive head drive motor and other motors are precision balanced for power and long life. Totally enclosed, fan-cooled motors add durability.

Anti-Kickback Assembly: Heavy duty steel “fingers” (chipbreaker) mounted on the infeed of the machine to prevent material kickback during operation.

Sectional Infeed Shoe: Two-inch wide, pre-loaded holddown shoe segments prior to cutterhead provide uniform holddown pressure when processing parts of various thicknesses.

Dual Infeed and Dual Outfeed Holddown Rolls: Rubber-covered, spring-loaded rolls aid in holding parts onto the conveyor as they pass through the machine.

Air Operated Disc Brakes: Used to stop the abrasive head to assure consistent abrasive belt stoppage in approximately four seconds. This braking system will not fade under continuous braking and has non-sparking, easily replaceable linings. The brake disc is located on the main motor shaft for easy maintenance.

Motorized Thickness Adjustment: Conveyor bed setting is motor driven. Allows for changes in thickness settings of material to be processed.

Four Jack Bed Construction: Four heavy duty precision jacks, one supporting each corner of the conveyor bed assembly.

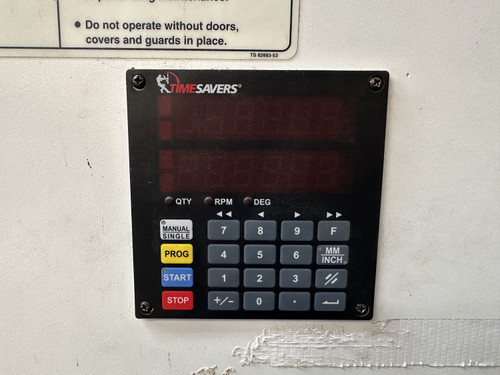

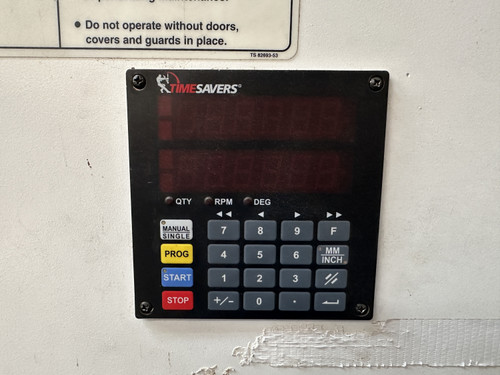

Centralized Control Panel: Simple operator controls for machine operation. Conveyor feed and abrasive belt heads are controlled at this centralized location.

Dial Indicators on Adjustable Drum/Platen Heads: Allows fine tuning of abrasive belt pressure on parts without the need to adjust holddown rolls. Also allows the possibility of running abrasive belts of different thickness without having to adjust holddown rolls.

Infeed Stop Bar: A sheet metal gate acts as an emergency stop for the operator when loading the machine. The gate actuates a limit switch, which shuts down the abrasive belt heads and conveyor in emergency situations.

Hour Meter: Records the actual running time of the machine. This unit is used by maintenance for scheduled lubrication of key components.

Main Motor Percentage Load Meters: Provided on each sanding head to show the exact percentage of main motor horsepower being used during operation.

Through-Beam Abrasive Belt Tracking: Electronic photo-eye tracking which monitors and controls abrasive belt movement on the grinding head. Over-travel limit switches prevent abrasive belt damage in case of mistrack.

Quick Release Outboard Support: Allows fast removal of outboard support to expedite abrasive belt change. Abrasive belts can be changed in approximately one minute.

Electronic Go-To Device: Allows user to digitally enter desired machine opening position. Indicates conveyor speed and conveyor bed position in relation to sanding belt for accurate setup to .001”. The device can store up to ten programs.

Variable Speed Conveyor Device: 15-45 FPM A/C variable frequency conveyor drive allows operator to change feed speed by simply turning a dial, even while running parts.

U.L. Listed Components: Includes main motor fusing, electrical disconnect, Star Delta starters and 110 volt control circuit.

Spare Platen Assembly: Extra 2 ½” wide platen assembly on dove-tailed slide for quick, easy removal and installation.

Knife Head Maintenance Kit: Includes insert wrench, air tool with regulator and supply of extra inserts and insert screws.