Product Description

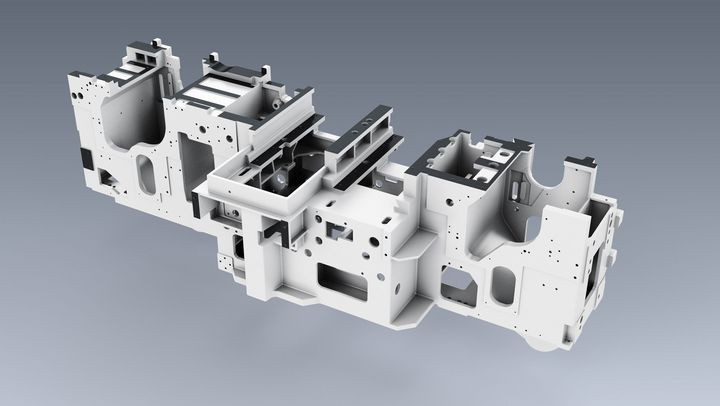

WEINIG SOLID PROFILE H 3000: The robust moulder for entry into the SOLID PROFILE H series

The variety of products in industrial solid wood processing is immense. However, no matter which market you are servicing, with the SOLID PROFILE H 3000 you have a wood processing machine that will meet your performance requirements. The SOLID PROFILE H 3000 offers you both a high-performance platform for the demanding requirements of everyday multiple shift operation.

Whether planing beams and/or producing mouldings – we can build the ideal SOLID PROFILE H 3000 for your requirements. With feed speeds of up to 100 m/min, jointing technology and robust pressure elements, it offers the best prerequisites for serial production in legendary WEINIG surface quality. The SOLID PROFILE H 3000 is truly state-of-the-art technology in profiling.

By upgrading the machine with the PowerMech automation system, you can increase efficiency significantly further. The PowerMech modules are the key to maximum profitability and optimal productivity. The functional units range from an infeed or outfeed system through scanning and conveying to packing and stacking. With the high level of automation you can decide how far you want to exploit the amazing capabilities of your SOLID PROFILE H 3000.

Machine infeed

Depending on the condition of the raw material, it may be advisable to strengthen the machine infeed. Particularly with bent, damp or heavy pieces, it is advisable to have a strong machine infeed that supports the transport of parts through the machine.

The 3-roller infeed ensures optimal feeding force for strips and boards, particularly when combined with infeed mechanization. A heavier version is available in the 4-roller infeed with two opposing roller pairs. In either case, it is not possible to straighten the work piece.

HydroLock outboard bearing

Hydraulic outboard bearings and fast, convenient tool changing have long been mutually exclusive. But now the HydroLock system is revolutionizing both the (dis)assembly of the outboard bearing and tool changing.

With the HydroLock outboard bearing, time-consuming set-up using a grease gun is a thing of the past. Instead, only an Allen key is required to compress the grease chamber and build up the required pressure. A pin is used to check the tension. In combination with the HydroLock tools, this results in a conclusive operating concept that is both simple and time-saving!

Jointing system

Jointing technology and hydro tools produce excellent surface quality. In the SOLID PROFILE H 3000, you can choose this combination and benefit from it: Jointed tools developed by WEINIG ensure that all knives in the cutterhead have an absolutely identical cutting circle. Both the fully automatic straight jointer for four-sided planing and the fully automatic profile jointer can be used.

The jointers automatically move with the spindle during radial adjustment, so that no manual intervention is necessary. WEINIG know-how and experience guarantee complete process reliability of our leading edge technology.

SOLID PROFILE H 3000 technical data

| Working height min./max. | 10/160 mm |

| Working width min./max. | 20/230 mm |

| Working width 30 - 310 mm, speed max. 6,000 rpm with HydroLock outboard bearing | Option |

| Maximum work dimensions | 310 x 200 mm |

| Comfort Set operating concept | Standard |

| Spindle speed 6,000 rpm | Standard |

| Spindle speed 8,000 rpm (not with HydroLock outboard bearing) | Option |

| Frequency-controlled speed 4,000 - 8,000 rpm | Option |

| Start and stop of all spindle drives via frequency converter | Option |

| Memory Plus control | Standard |

| PowerCom Plus control | Option |

| Max. tool diameter horizontal spindles (except first lower spindle) | 250 mm |

| Max. tool diameter, vertical spindles | 250 mm |

| HydroLock outboard bearing | Option |

| Straight jointer / profile jointer, fully automatic | Option |

| Frequency controlled feed speed 6 - 60 m/min | Standard |

| Frequency controlled feed speed, 8 - 80 / 10 - 100 m/min | Option |

| MarathonCoating for machine table and stop | Standard |

| Max. motor power on vertical spindle (standard - option) | 7.5 - 22 kW |

| Max. motor power on horizontal spindle (standard - option) | 7.5 - 37 kW |

| Improved sound enclosure | Option |