Product Description

WEINIG SOLID PROFILE P 700: The new generation of moulding and planing

With the introduction of the SOLID PROFILE P series in the year 2004 WEINIG began a new era for planing and profiling. Now, with the SOLID PROFILE P 700 the next generation has arrived; offering undreamt-of possibilities.

The SOLID PROFILE P 700 is designed with a revolutionary new operating concept which no other moulder can offer. The result: improved ease of operation and very short setup times offer the highest degree of flexibility. With these outstanding qualities the new SOLID PROFILE P is the perfect response to the market demands of today and sets a new standard for four sided

Technical Details:

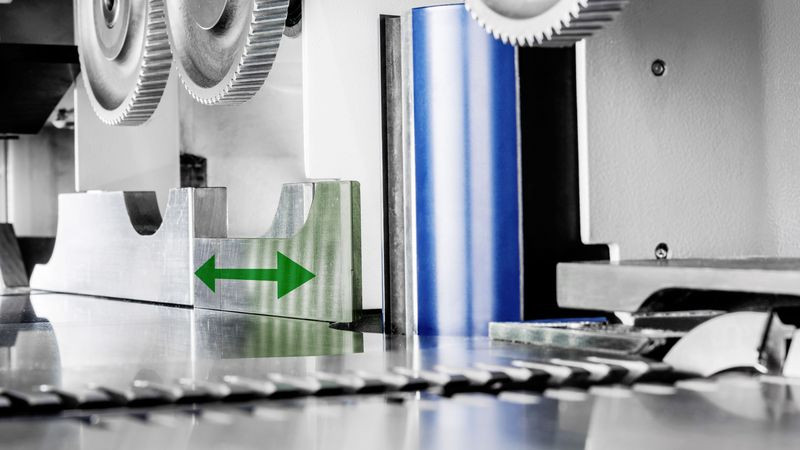

Operating concept Comfort Set

The new operating concept Comfort Set comprises a great number of wrench-free adjustments for pressure and guiding elements which can be performed quickly, accurately and without error. With features like this the machine operator will experience a new degree of comfort in performing the moulder setup like he never experienced before. The final proof of the new setup procedure can also be seen in the quality of the products you produce.

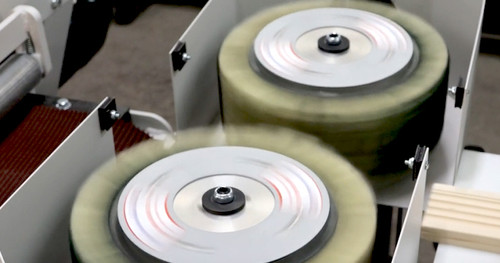

Performance:

With 7,000 rpm spindle speed in standard the new SOLID PROFILE P 700 offers even more performance. This means more linear production every day without sacrificing high surface quality. Compared to conventional moulders, the production increase is up to 15%.

The option of 8,000 rpm spindle speed allows an even higher increase, which perfectly meets the current requirements in terms of productivity and cost effectiveness.

Technical data SOLID PROFILE P 700

| Working height min./ max. | 10/ 160 mm |

| Working width min./ max. | 20/ 230 mm |

| 260 mm working width | Option |

| 200 mm working height | Option |

| 7,000 rpm (not first bottom) | Standard |

| 8,000 rpm | Option |

| Operating concept Comfort Set | Standard |

| Memory Plus | Standard |

| PowerCom Plus | Option |

| Electronic read-outs | Standard |

| CNC-controlled axis-adjustment | Option |

| Receding chip breaker | Option |

| Max. horizontal tool diameter (not first bottom) | 200 mm |

| Max. vertical tool diameter | 200 mm |

| PowerLock tool holders | Option |

| Universal tool holders | Option |

| Frequency-controlled feed speed (standard) | 5 - 40 m/min |

| MarathonCoating for machine tables | Option |

| Max. motor power on vertical spindle (standard – option) | 5.5 - 15 kW |

| Max. motor power on horizontal spindle (standard – option) | 5.5 - 15 kW |

| Improved sound enclosure | Option |